What Are the Advantages of CNC Plasma Cutting Over Other Cutting Methods?

CNC plasma cutting offers numerous benefits compared to traditional cutting methods. Outaouais Welding & Machining highlights why CNC plasma cutting is an excellent choice for precision and efficiency in metal fabrication.

Speed and Efficiency

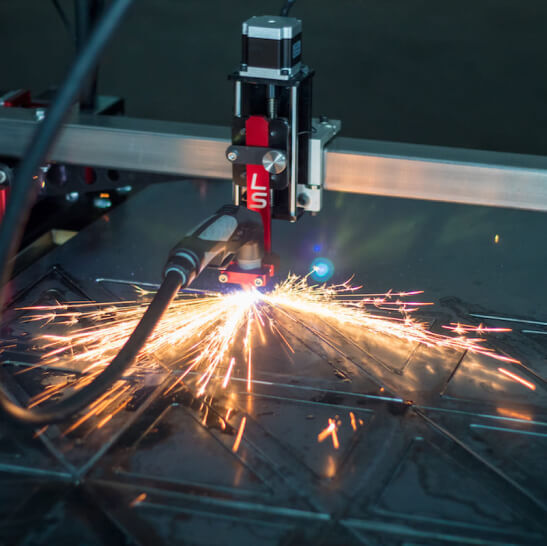

One of the primary advantages of CNC plasma cutting over other methods is its speed. Plasma cutting is faster than conventional methods like laser or water jet cutting, especially when dealing with thicker materials. The plasma torch can cut through metals at a much quicker rate, making it a highly efficient choice for large-scale projects or when time is a critical factor.

At Outaouais Welding & Machining, we utilize CNC plasma cutting to maximize productivity while maintaining precision. This speed allows us to meet tight deadlines without sacrificing quality, ensuring that your project is completed on time and within budget. The efficiency of CNC plasma cutting also translates to reduced labor costs, as fewer manual adjustments are required, allowing our team to focus on delivering quality results faster.

Cost-Effectiveness and Versatility

CNC plasma cutting is also more cost-effective compared to other cutting methods. The technology is generally more affordable than laser cutting, making it an excellent choice for businesses or projects with a limited budget. Additionally, plasma cutting is highly versatile, capable of cutting through a wide range of materials such as steel, stainless steel, aluminum, and even non-ferrous metals like brass and copper.

Outaouais Welding & Machining uses CNC plasma cutting to handle various projects, from custom metal fabrication to large-scale industrial production. The versatility of this method makes it a great option for industries ranging from construction to automotive. With its ability to cut multiple materials efficiently, CNC plasma cutting offers significant savings while delivering high-quality, precise cuts across different applications.